To improve fuel efficiency and congestion, the United States should build a network of urban truck ports—where drivers swap freight. Rural drivers would use tractors designed for the long haul, and urban drivers would use tractors designed for city driving.

Why Truck Efficiency Matters

Tractor-trailers move just about everything in our economy at some point. Every day they carry billions of pounds of freight millions of miles. They are also really large consumers of energy, users of our highways, and producers of pollution—including greenhouse gas emissions and air pollutants. Sadly, tractor-trailers aren’t nearly as efficient as they could be. That means we are all paying more for the goods we consume—and not just in the final price at checkout. We also pay for trucking’s inefficiencies through more congested highways, greater infrastructure costs, accidents, pollution-related health care costs, and greater dependence on fossil fuels. The amount of freight moving by truck is forecasted to increase by more than 40% by 2045 (USDOT 2016a). So if we don’t do something to make them more efficient, these problems are only going to get worse.

There are solutions available right now that could double the fuel efficiency of the average tractor-trailers. Unfortunately, the industry is not adopting these solutions fast enough or, in many cases, at all because they can’t ensure a good return on investment given the way trucks are currently used. While there are some important proposals, such as stronger fuel efficiency regulations, that will help, we can and should do a lot more to improve the efficiency of trucks by making public investments in infrastructure that make the use of more efficient trucks a no-brainer for the industry.

It will be well worth the investment to focus specifically on trucks. The average passenger vehicle burns about 620 gallons of gasoline per year,1 but a typical long-haul tractor-trailer can burn more than 16,000 gallons of diesel per year.2 Because trucks burn so much fuel per vehicle, they represent one of the best opportunities we have to quickly decrease our nation’s oil use and greenhouse gas emissions and reduce the cost of goods movement. The right kind of infrastructure—one that leverages the public’s investment to maximize energy efficiency—can help us take advantage of that opportunity. Outlined below is a solution that will dramatically change the return on investment (ROI) for fuel efficient technology. This solution will not only help the industry save money, but improve urban air quality and reduce traffic congestion, all while making trucks safer and the lives of truck drivers better.

A Solution to Foster Efficiency

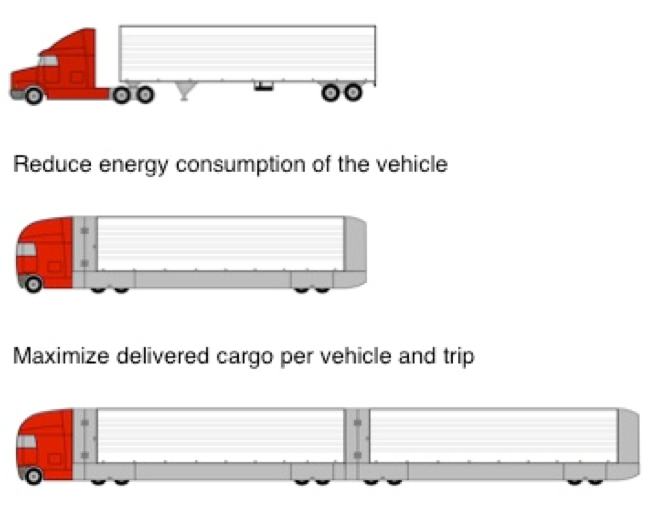

The United States should build a network of Urban Truck Ports at the key points of road congestion around our major cities. Like a port where the ocean meets the land, truck ports would be placed where the urban meets the rural. Each port would provide a place where two different kinds of tractors—one designed to haul trailers in rural areas and one designed for urban areas—can meet up to swap trailers. At their simplest, these ports would be little more than large parking lots where tractors can drop-off and pick up trailers. By splitting up trips by the type of driving required and the best tractor for each, these ports would allow the industry to:

- invest in the best technology for each kind of driving;

- avoid driving through rush hour;

- bring drivers home more often.

If trucking companies were able to do those three things it could save the industry billions of dollars annually in fuel ($32 billion if we could double the fuel economy of trucks),3 congestion, and driver turnover costs. Much of that savings would be passed on to consumers. It would save all of us in time spent waiting in traffic and the health costs of air pollution caused by trucks. And by utilizing our most congested roads at off-peak times, a nation-wide network of such ports would substantially reduce the need to build expensive new roads to meet increasing demand.

Truck Efficiency—Roads Not Taken

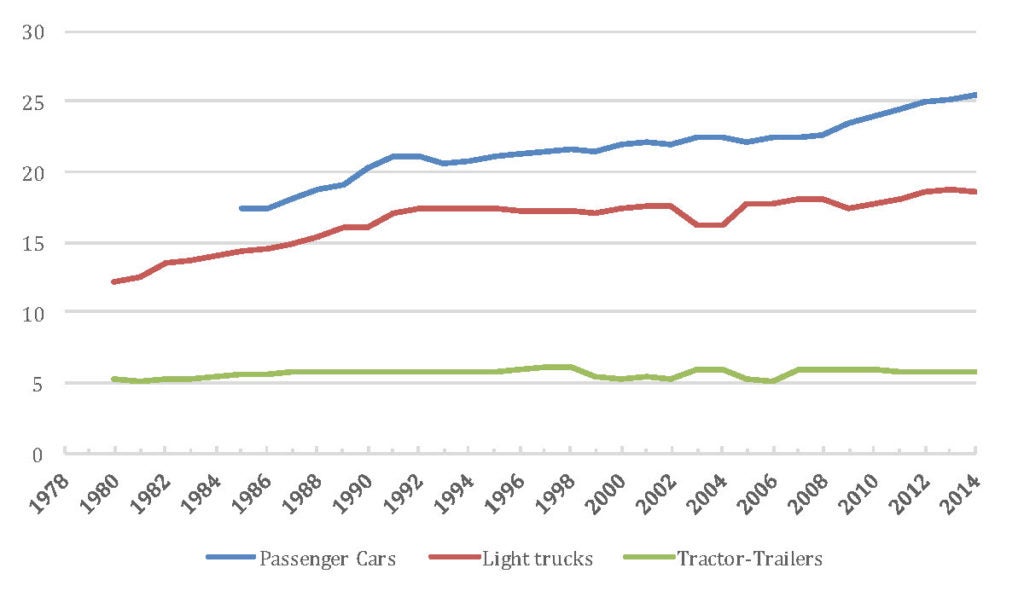

About 70% of the oil the U.S. consumes goes to transportation. In 2014, about 10% of total U.S. oil consumption—roughly 28 billion gallons—was burned by tractor-trailers (USDOE). Though Class 8 tractor-trailers (those weighing more than 29,000 lbs) represented only about 1% of all vehicles, these vehicles burned roughly 22% of all transportation fuel (USDOT 2015; USDOE). And their share of oil consumption has been growing, because, as the figure below suggests, the efficiency of other kinds of vehicles has vastly improved while the fuel efficiency of tractor-trailers has barely budged for decades.

The flat line for tractor-trailers in Figure 1 is remarkable when we consider that trucking spends a lot on fuel—30-40% of total costs in some segments (Torrey and Murray 2014). What makes it even more remarkable is that for more than 50 years the potential of readily available technology to dramatically increase fuel economy has been demonstrated over and over again. In fact, truck manufacturers have repeatedly produced tractor-trailers with twice the fuel economy of existing trucks.

Today’s super trucks get more than twice the fuel economy of the average heavy truck. If all trucks in the U.S. used the existing technology on this truck it would save 12.6 billion gallons of diesel annually and could save operators more than $20,000 annually per vehicle.

Why Fuel Economy Hasn’t Improved

History suggests trucking companies are not going to adopt fuel-efficient technology on their own. But why? Overall, trucking is a conservative industry when it comes to technology and innovation. There are some pretty good reasons for that. First, trucking has been a relatively low-margin business for decades now. The industry figures out the costs and benefits of its investments in the fractions of a penny per mile. Long-haul trucks, which burn the most fuel, can cover 100,000 or more miles in a year and are sent far from company facilities, making reliability and maintenance costs fundamental concerns about new technology. For these reasons, many companies don’t keep trucks in long-haul service very long—4-5 years at most firms. This means technologies have to have a return on investment (ROI) that pays off in a relatively short period of time.

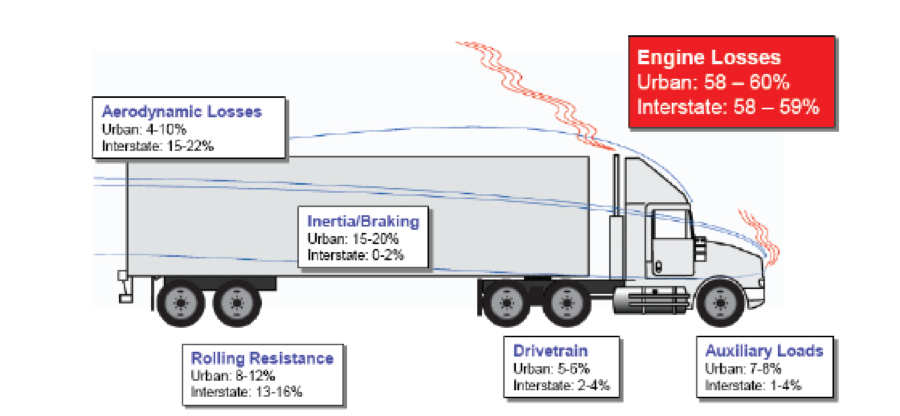

The biggest problem for many new truck technologies in terms of ROI is that long-haul trucks have to operate in two very different environments. Much of the time they are traveling at high speeds on interstates. But increasingly, the typical long-haul truck also has to spend a lot time in congested suburban and urban areas. This mix of rural or urban driving is called the “duty-cycle.” In the case of long-haul trucks, very few technologies can improve efficiency over the entire duty-cycle. Most of the best new technologies provide most of their benefit in one type of driving environment and little or none in the other. Some technologies are even problematic in the portion of the duty cycle they don’t provide a benefit in.

For instance, when trucks are traveling fast on the interstate, they lose a lot of energy to aerodynamic drag. And there is plenty we can do right now to make them more aerodynamic. You may have noticed over the last few years tractor-trailers with extra pieces of fiberglass underneath the trailer (known trailer skirts) or sticking out from the back of trailer doors (known as boattails). These features change the way air moves over the truck when it’s going fast and can save thousands of dollars in fuel annually.

But these features provide no benefit at all during urban driving. We could make even greater aerodynamic improvements by doing things like closing the gap between the tractor and trailer entirely and adding additional trailers. But improvements like these can become a problem in urban areas where trucks have to make tight turns backing up or may encounter other obstacles that damage these features.

In contrast to interstate trucks, city trucks could use available technologies like hybrid engines that capture energy from braking. Those trucks would be quieter and pollute our air less, saving all of us in health care costs. But hybrid engines are expensive and provide almost no benefit when trucks are moving through rural areas at high speeds. Urban trucks would also have maximum visibility and be designed for safety on congested roads.

These are just a couple of examples of dozens of upgrades we could make to trucks right now. Urban Truck Ports would allow firms to invest in two different types of trucks that could be highly specified to operate in either urban or rural environments. This would dramatically improve the ROI of many of the most promising technologies available today. It would also spur innovation of new technologies. Unfortunately, no truckload firms are large enough to afford to place truck ports at multiple locations around major cities for their use alone. And, because drivers are often unpaid or paid relatively little for urban driving, firms have less incentive to segment the duty-cycle by contracting with a local fleet for urban delivery.

Truck Port Benefits for Congestion

Experienced truckers plan very carefully to avoid congested traffic conditions. They will alter their driving times by changing their work and sleep hours to reduce the amount of driving they do in congested conditions. But due to appointment times, routes they must take and the way their work hours are regulated by the government, there is often a disincentive for truckers to stop rather than drive through congested conditions. Essentially in most cases, if a driver is coming up to a congested area they have a choice of driving through at slower speeds (reducing their pay since most are paid by the mile) or stopping and not get paid at all. As a result, in all U.S. cities every morning and night, hundreds of thousands of trucks contribute to our congested roads.

If truckers and their employers had the choice, they would avoid driving in rush hour traffic entirely. If we made that possible, it would reduce congestion and fuel consumption for both trucks and cars resulting in less fuel cost, wasted time and air pollution. And it would reduce the need for costly new roads and road expansion. Urban Truck Ports would mean that interstate trucks could drop their trailers outside of congested areas, pick up a trailer heading in the opposite direction and head back where they came from without passing through congested traffic bottlenecks. After rush hour, an urban truck could come and finish the delivery. This could even happen at night, a process known as off-peak delivery. There is great potential for off-peak delivery to enhance the efficiency and safety of our freight system, including getting shipments there faster than a single driver whose driving hours are currently limited by safety concerns and regulations.

Rather than building expensive, new roads, Urban Truck Ports would help us make more efficient use of the tremendous road infrastructure we already have, most of which sits relatively unused for most of the day and is then choked with congestion for a few hours every weekday morning and afternoon.

Truck Port Benefits for Truckers

For the past several decades, the long-haul truckload segment of the U.S. trucking industry, which would benefit most from Urban Truck Ports, has suffered a severe labor crisis. The industry has extraordinary rates of turnover—many large firms have turnover above 100% annually, meaning they hire and train on average one driver for every truck they operate. While some drivers stick around for more than a year, most stay in the industry much less and these less experienced drivers are far less fuel-efficient and safe drivers.

One of the major causes of high turnover is the fact that truckload firms often send their trucks from one customer location to another across wide areas for weeks at a time. All this time drivers are away from home and family and living out of their trucks—an expensive asset for firms that sits idle while drivers sleep. This lifestyle makes the job very hard to do for long. In addition to the lengthy time on the road, most over the road drivers are only paid for the number of miles they drive, which means they are often working for little or no pay when they are in urban environments.

A network of Urban Truck Ports would result in tremendous cost savings and efficiency gains for the trucking firms and make it much more profitable for companies to send trucks back and forth between particular ports. Drivers would get home regularly, get consistent pay for their time on the job, and likely have more job satisfaction (less turnover). Ports would also create more local driving jobs, meaning that drivers could work doing interstate driving some of the time and local driving at other times.

Making Urban Truck Ports a Reality

The potential benefits of an Urban Truck Port Network are enormous. A wide range of stakeholders from cities to trucking firms to highway safety advocates have goals that could be more easily advanced by segmenting the duty cycle of long-haul trucks. At the moment there appears to be substantial bi-partisan support for reinvesting in our ailing road infrastructure. Given the need for additional road capacity for freight and the cost of alternative means for achieving it (i.e. building new roads and adding lanes), the choice of better utilizing our existing road capacity by shifting demand time is clearly an alternative to explore more fully. In fact, the cost of building Urban Truck Ports, which could begin by simply building large parking lots, will be a fraction of the cost of alternatives.

Because these ports would affect trucking operations nationwide, the U.S. DOT should lead the effort to research and develop an Urban Truck Port Network. One way to pay for and incentivize the use of these facilities would be to add a federal tax to diesel fuel. In fact, in recent years the trucking industry has proposed a 10¢ per gallon tax on diesel as a way to pay for truck-related infrastructure. One way to incentivize the use of Urban Truck Ports would be to refund a portion of that fuel tax to firms based on their use of the facilities rather than driving through congestion. This would simultaneously pay for the infrastructure and serve as a form of congestion pricing.

The size, importance, and externalities of our freight system are continuing to grow. It is time to rethink the way we move freight and to develop a more efficient system. Urban Truck Ports could serve as a critical foundation for developing a truly 21st-century freight transportation system.

The author wishes to acknowledge helpful comments from Dr. James Hines of an earlier draft and research assistance from Peter Thacher. Any remaining errors are the responsibility of the author alone.

Steve Viscelli

Lecturer, Department of SociologySteve Viscelli is a faculty fellow at the Kleinman Center and a lecturer in the Department of Sociology. His research focuses on work, labor market economics, and economic regulation, specifically in trucking industry.

Torrey, W. Ford, and Dan Murray. An Analysis of the Operational Costs of Trucking: A 2014 Update. Arlington, VA: American Transportation Research Institute, 2014.

Oak Ridge National Labratory. 2016. “Transportation Energy Data Book. http://cta.ornl.gov/data/download35.shtml (accessed 3/15/2017).

Rocky Mountain Institute. 2009. “Transformational Truck Initiative Report v1.0.” www.move.rmi.org/transformationaltrucking (accessed 3/15/2017).

Transportation Research Board. Technologies and Approaches to Reducing the Fuel Consumption of Medium- and Heavy-Duty Vehicles. Washington: National Academies Press, 2010

TransPower. “Yard Tractors.” http://www.transpowerusa.com/yard-tractors/ (accessed 3/15/2017).

U.S. Department of Energy. “SuperTruck Leading the Way for Efficiency in Heavy-Duty, Long-Haul Vehicles.” Office of Energy Efficiency and Renewable Energy. https://energy.gov/eere/articles/supertruck-leading-way-efficiency-heavy… (accessed 3/14/2017).

U.S. Department of Transportation. 2015. “State Motor-Vehicle Registrations – 2014.” https://www.fhwa.dot.gov/policyinformation/statistics/2014/pdf/mv1.pdf (accessed 3/14/2017).

U.S. Department of Transportation. 2016a. “2016 Freight Quick Facts Report.” Federal Highway Administration. https://ops.fhwa.dot.gov/publications/fhwahop16083/index.htm (accessed 3/14/2017).

U.S. Department of Transportation. 2016b. “Average Annual Miles per Driver by Age Group.” Federal Highway Administration. https://www.fhwa.dot.gov/ohim/onh00/bar8.htm (accessed 3/14/2017).

U.S. Department of Transporation. 2016c. “Table 4-23: Average Fuel Efficiency of U.S. Light Duty Vehicles.” Bureau of Transportation Statistics. https://www.rita.dot.gov/bts/sites/rita.dot.gov.bts/files/publications/n… (accessed 3/14/2017).

- The average driver travels 13,476 miles per year and the average mpg of light-duty vehicles in the U.S. is 21.8 mpg.

13,476/21.8= 618.2. [↩] - The vehicles most relevant to this proposal are long-haul tractor-trailers working in the for-hire truckload segment and travel roughly around 100,000 miles per annually. They average somewhere around 6 mpg in fuel economy. 100,000/6=16,666. [↩]

- If we could save 12.8 billion gallons of fuel as suggested below at $2.50 for diesel (the price as I write this) that works out to 32 billion dollars. [↩]