The Calculus on Direct Air Capture

In the push to decarbonize, it is crucial that we consider the local implications of new energy technologies. This is true for direct air capture, or DAC, a technology that the Clean Energy Conversions Lab at Penn are studying closely.

Welcome to the stage, Direct Air Capture (DAC). DAC is a technology designed to extract carbon dioxide directly from the surrounding air, playing a vital role in achieving our climate objectives, including those outlined in the Paris Agreement.

But with rapid-scale climate mitigation on our collective minds, it is crucial that we consider the local implications of new energy technologies. This holds true for DAC, which we at the Clean Energy Conversions Lab at the University of Pennsylvania are closely studying.

How DAC Works

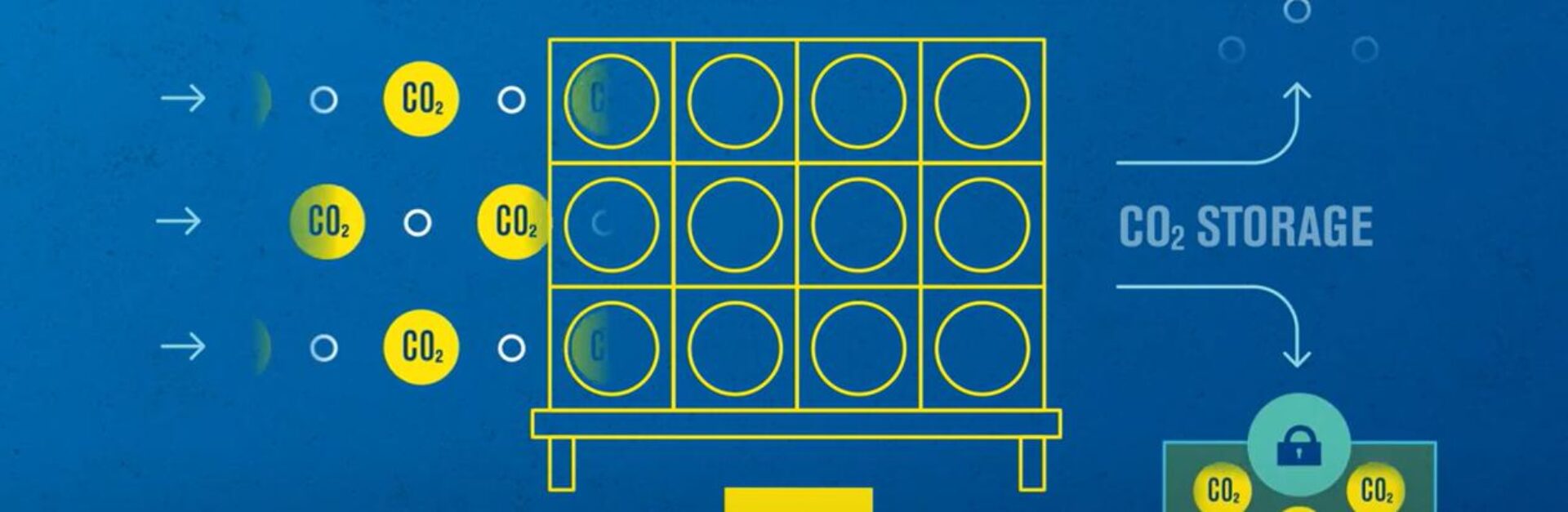

While there are many approaches to DAC, most follow this two-step formula:

Step 1: Ambient air flows through building-like structures where CO2 sticks to specially formulated chemicals or surfaces.

Step 2: Trapped CO2 is released by applying heat or electricity in a controlled way. The end result is a separate stream of CO2 that can be compressed and sent to storage, keeping it out of the atmosphere for many years to come.

More About DAC

DAC plants can be located anywhere, but some locations make more sense. Regions with both low-carbon energy potential and CO2 storage potential are ideal. For example, a DAC plant powered by geothermal at a location with on-site underground storage will produce fewer emissions than a DAC plant powered by fossil fuels that also requires transporting CO2 to a distant location.

Benefits of DAC

DAC has almost unlimited potential to remove carbon from the atmosphere. It doesn’t need to be placed on arable land, so it won’t take up valuable land required for crops and other nature-based solutions, like planting trees. DAC is a pathway to durable carbon removal, meaning that when designed properly keeps CO2 out of the atmosphere for a very long time. DAC has a much lower land footprint than some other solutions, meaning it takes up less space. And DAC has the potential to be a strong local economic driver, bringing permanent, good-paying jobs to the area.

Risks of DAC

Some fear that DAC, and carbon dioxide removal in general, enables us to continue emitting without concern (like exercising to justify that ice cream sundae). Use of bulk chemicals for CO2 removal could present an environmental hazard risk at the site or along upstream or downstream transport of materials and spent reagents.

The same risk applies to transporting CO2 to storage when co-location is not possible. While land intensity remains lower than other solutions, the scale of DAC required for our climate goals will still require vast amounts of land. These impacts must be carefully examined in order to avoid environmental disruption and negative community impacts.

Cost of DAC

It is estimated that DAC will cost $400-$1000 per metric ton of CO2 in the near term, which can be reduced by up to $180 from government tax credits. A few large corporations are customers for these initiatives to help reach their net-zero goals, which results in revenue for the carbon removal service. The revenues from this service can benefit local communities who are hosting these DAC plants through community benefit agreements with the project developers.

Today, the largest DAC plant in operation, Orca in Iceland, captures 4,000 tons of CO2 per year, and a new facility will soon capture 36,000 tons of CO2 per year next door. Project Bison in Wyoming is intended to capture 10,000 tons of CO2 per year by 2024, growing to 5 million tons of CO2 per year by 2030.

As new plants roll out, more of us will find DAC coming to a community near us. If DAC comes knocking on your door, here are some of things that your community might ask about or push for:

- Noise: How much noise is produced from the plant?

- Design: What will the plant look like? Can we blend it into the landscape?

- Health: Does DAC bring any unwanted socio-environmental risks to my community?

- Resources: How much water or other resources will the DAC plant require?

- Jobs: How many jobs will the DAC plant bring to my community?

Peter Psarras

Research Assistant Professor of Chemical EngineeringPeter Psarras is a research assistant professor in chemical and biomolecular engineering at the School of Engineering and Applied Sciences and the Kleinman Center for Energy Policy.