The Sky Isn’t Falling

Direct air capture (DAC) can face skepticism as a climate mitigation tool on account of high costs. These costs shouldn't be viewed as alarming but rather as the necessary growing pains of the nascent industry.

“When will direct air capture (DAC) costs hit $100 per ton?” It’s probably the most common question I hear when it comes to DAC economics. DAC, an up-and-coming energy technology that removes CO2 directly from the atmosphere, is seeing a recent surge in interest and activity, with the recent DOE DAC hub announcement that will bring two large-scale DAC projects to U.S. soil, and large, record-breaking purchases from Amazon and Microsoft.

Yet, DAC continues to face skepticism as a climate mitigation tool on account of high energy intensity and high costs. While the public and private sector alike anxiously await DAC cost reductions (the government embodied this in their $100/tCO2 “Carbon Negative Shot” target), it is understandable how news like this week’s exposé on the leading commercial DAC company Climeworks, who recently updated their 2030 cost reduction targets from $200– $300/tCO2 to $400–$700/tCO2, can warrant a “chicken little” response. But should this news come as such a surprise and what we should make of it?

First, it’s important to recognize that CO2 is very dilute in the atmosphere at around 420 parts per every one million air particles. This means we must process a tremendous amount of air, and that means more infrastructure, energy, and cost.

As a thought experiment, imagine cleaning up 1,000 marbles that are loosely arranged on a kitchen table. Now imagine how much more work (or cost) it would take to clean up those marbles after someone tipped the table over, spreading those marbles all over the house. That’s DAC in a nutshell, and part of why DAC costs are so high today. It also underlies the importance of keeping CO2 out of the atmosphere in the first place.

Another cost driver is the small-scale modular nature of most DAC technical approaches. Small, modular systems struggle to capture economies of scale, those cost savings that are usually afforded to industrial processes as they “scale up.” This is attributable to the fact that larger machines are typically more cost-effective on a “unit processed” basis.

Modular DAC instead “scales out,” meaning equipment doesn’t necessarily grow larger with scale. Like using cinder blocks to build a larger wall: you don’t make the blocks larger, you just stack more of them together. While this may keep some DAC costs higher in the near term, modular components tend to see significant cost reductions over time through the standardization of manufacturing.

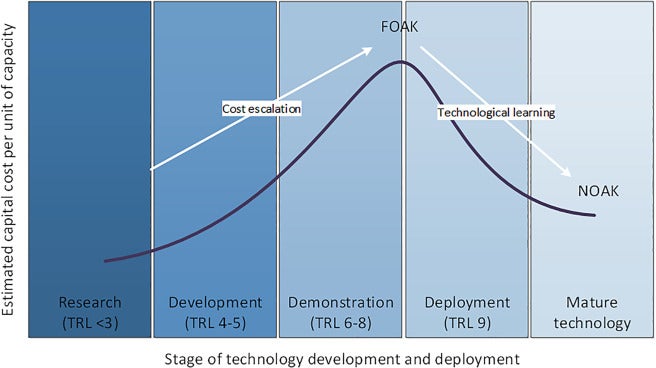

There’s another misconception here: that technologies become cheaper over time. While this is true in the long run, it is well documented that very early costs can escalate before falling due to legal and safety requirements, incomplete designs, and the need to engineer around issues identified in upscaling.

This shouldn’t be viewed as alarming, but rather as the necessary growing pains to position a technology for disruptive implementation in the coming years. Our analysis shows that even with these adjusted claims, DAC costs have the potential to reach that magical $100/t target by 2050.

Finally, part of the problem lies in trying to measure an industry that by and large does not yet exist. Maybe those rosy dataroom projections need some real world adjustments, and we should encourage every DAC company to consistently audit and transparently adjust their claims. What’s missing is data and if we are to realize our 2050 decarbonized future, we must push through those boundaries today. So as we look to the sky for a solution out of this mess, know that it isn’t falling.

Peter Psarras

Research Assistant Professor of Chemical EngineeringPeter Psarras is a research assistant professor in chemical and biomolecular engineering at the School of Engineering and Applied Sciences and the Kleinman Center for Energy Policy.