Tribology: An Obscure Word with Big Implications

Friction in engines and machinery results in energy losses, unnecessary carbon emissions, and lower productivity. By developing tribological solutions that address friction and wear and tear on moving parts, Rob Carpick unlocks energy efficiency gains in many sectors.

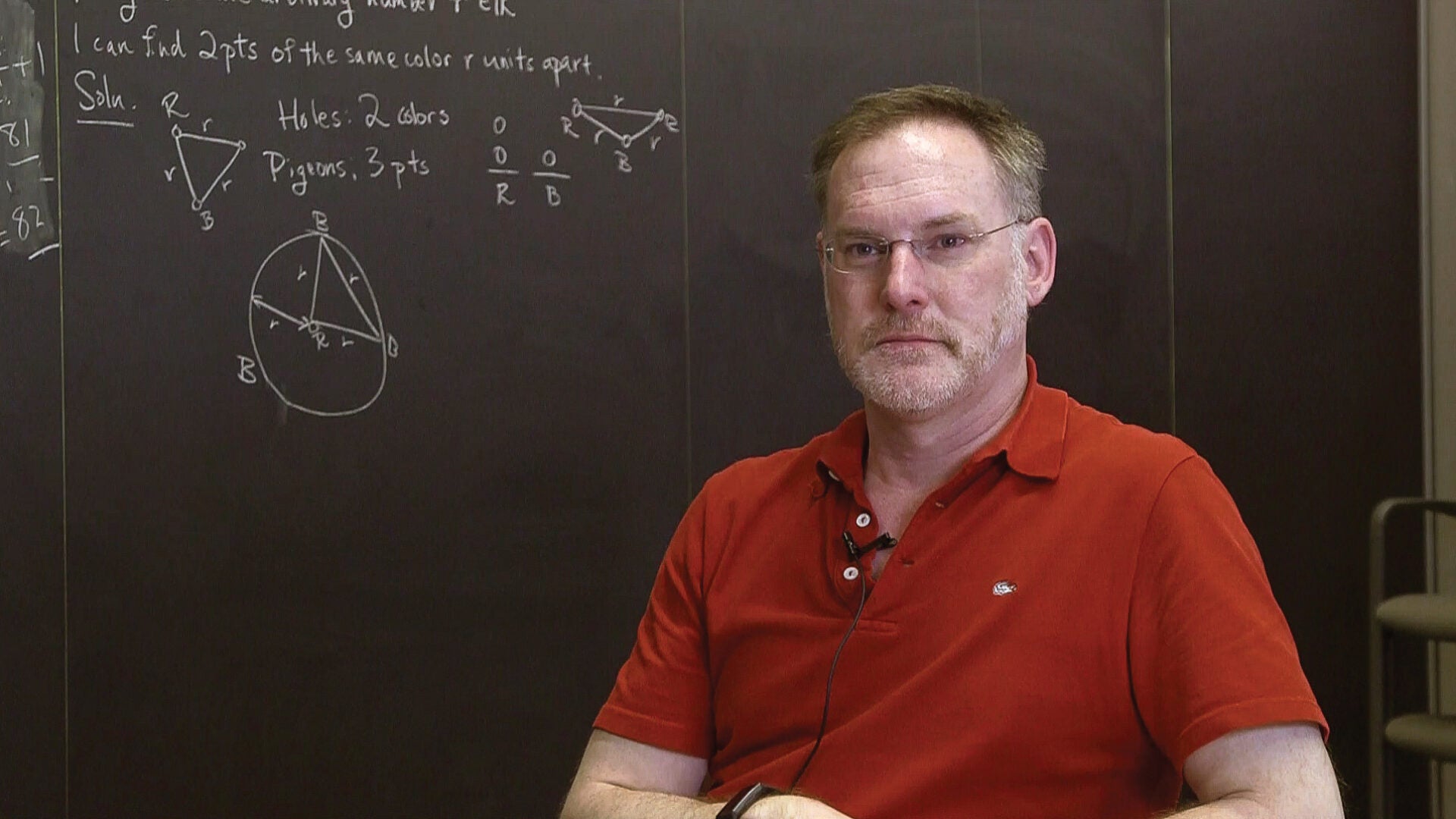

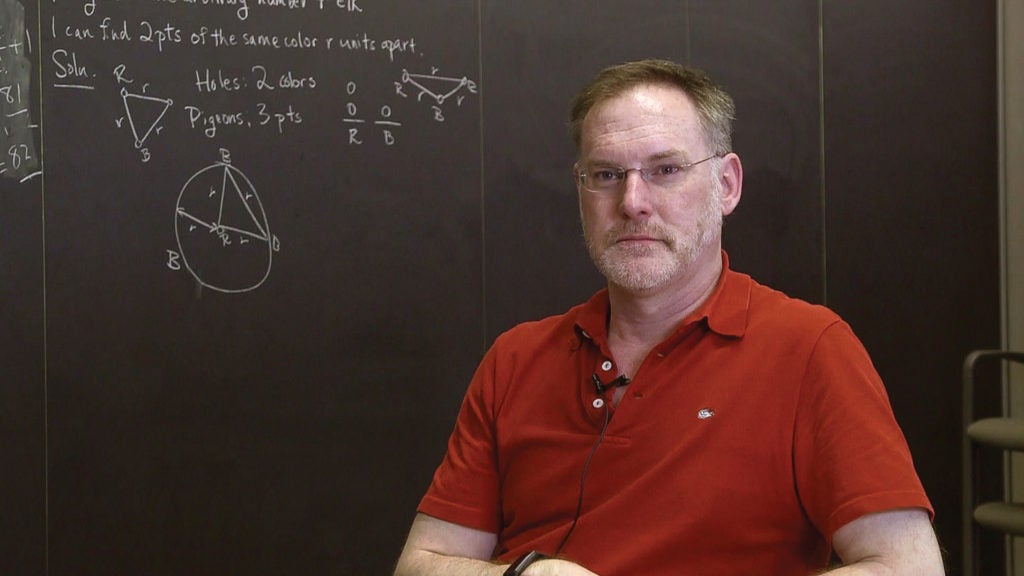

“Experts estimate that 10 to 20 percent of global energy is wasted on friction,” Professor Rob Carpick says, giving a glimpse of why tribology—the study of friction—is so integral to energy policy. Whether operating a wind turbine or a car engine, if there are moving parts, there is some amount of friction. Carpick is interested in the consequences of that wear and tear.

Energy is not only spent on friction, but on producing replacement parts. Obviously the less often a part needs to be replaced, the more sustainable it is. And many new green technologies, like energy-efficient switches and friction energy generators, can be advanced by tribology research.

Carpick’s research spans a number of areas, from studying how to reduce energy consumption in engines, to working with the Department of Defense on improving heavy vehicle efficiency in high-stress gears, to looking at the friction in nanoscale mechanical computer switches, which could make computing much more efficient.

“I’m lucky because I’m able to work in a very fertile area— fundamental engineering and science—where there are all sorts of fascinating problems to pursue to satisfy my curiosity and contribute to long-term development of knowledge. At the same time, it addresses immediate practical concerns of energy efficiency and use.”

One particular focus area is electric vehicles and other forms of e-mobility, like scooters. “We’re very excited about ways to enhance the tribology and therefore enhance the efficiency—of the performance and range of electric vehicles and e-mobility. We’re not only talking about potentially reducing or even eliminating the carbon footprint of vehicles, but also enabling new technologies like hoverboards and robotic assisted mobility and wheelchairs.”

Electric motors are quite efficient even with relatively basic lubricants and high amounts of energy losses due to friction. With continued research into improving the lubricants and tribology of e-mobility, Carpick envisions even greater efficiency.

While energy conservation is often driven by market dynamics, like oil prices, tribology has the potential to contribute to greater energy efficiency in power generation, advanced manufacturing, gas, aviation, and electronics. Tribology research can show how to achieve policy goals aimed at conservation, efficiency, and reducing greenhouse gas emissions.

Collaborating with government will be essential to the success of this work. “We’ve learned, in large part due to the Kleinman Center, how important it is to be aware of policy considerations,” Carpick says. “Often policy incentives are the way that technological innovations will end up being applied.”

Policy Challenge

Using tribology to improve the energy efficiency of existing technologies anddeploy new energy technologies can produce economic and environmental benefits. Their adoption, however, is lengthy and may not happen without policy intervention. Low energy prices and a myopic view of future benefits are among the reasons that prevent a widespread and quick adoption. EPA and DOE regulations can facilitate the adoption of tribology technologies like emissions standards for engines, energy efficiency standards for manufactured products, and even energy performance indicators for manufacturing plants and products.

The Numbers

Machine driven processes such as pumps, fans, compressed air, and materials handling and processing account for 68 percent of electricity use. Energy intensity in manufacturing in the United States decreased from 2010 to 2014 by 4.4 percent. The IEA reports that without the efficiency improvements that have been made in the industry and service sectors since 2000, energy use in 2017 would have been 20 percent higher.

Further Reading

We’re very excited about ways to enhance the tribology—and therefore enhance the efficiency—of the performance and range of electric vehicles and e-mobility.

Robert Carpick